Thermographic Inspections

Thermography measures surface temperatures by using infrared video and still cameras. These tools see light that is in the heat spectrum. Images on the video or film record the temperature variations of the building's skin, ranging from white for warm regions to black for cooler areas. The resulting images help the auditor determine whether insulation is needed. They also serve as a quality control tool, to ensure that insulation has been installed correctly.

Utility Plant Solutions has a number of applications for Thermography, including:

Utility Plant Solutions has a number of applications for Thermography, including:

Steam Trap Surveys

Several methods are used to test the operating condition of a steam trap to determine if it is working properly, including visual observation, measuring temperature (via thermographic scope), measuring sound/vibrations or ultrasound, and some combination of these methods.

Utility Plant Solutions offers the full service of steam trap analysis including a customer service report, that details the problematic traps. Upon request, we will replace defective traps with new traps by one of our qualified technicians. Order a steam trap survey by clicking here, or call us directly at 919-801-6452.

Utility Plant Solutions offers the full service of steam trap analysis including a customer service report, that details the problematic traps. Upon request, we will replace defective traps with new traps by one of our qualified technicians. Order a steam trap survey by clicking here, or call us directly at 919-801-6452.

Leak Detection

Thermography is the use of an infrared imaging and measurement camera to “see” and “measure” thermal energy emitted from an object. Thermography cameras can identify problem areas that cannot be seen with the naked eye, detecting hidden water leaks.

Inspections of Electrical Equipment

To identify excess heat on apparatus and detect electrical issues such as loose connections, faulty fuses, defective breakers, damaged switches, overloaded or imbalanced circuits and other problematic electrical conditions.

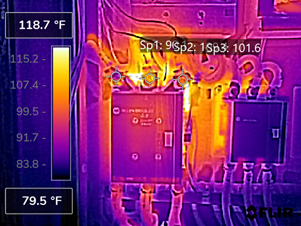

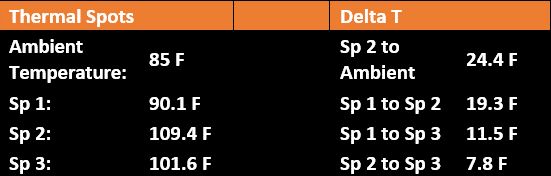

Example: Motor Starter

Observations:

The difference in temperatures of the lugs between each phase indicates a potential fault. The 'A' phase lug temperature to ambient temperature difference is within an acceptable range. The 'C' phase lug shows indication of minor concern. The 'B' phase lug shows indication of a potentially major concern.

Recommendations:

Isolate the motor starter and inspect the condition of each electrical connection. Verify the wires are in good condition, the conductors are clean and in good condition, and that the lugs are tightened to the proper torque specification.